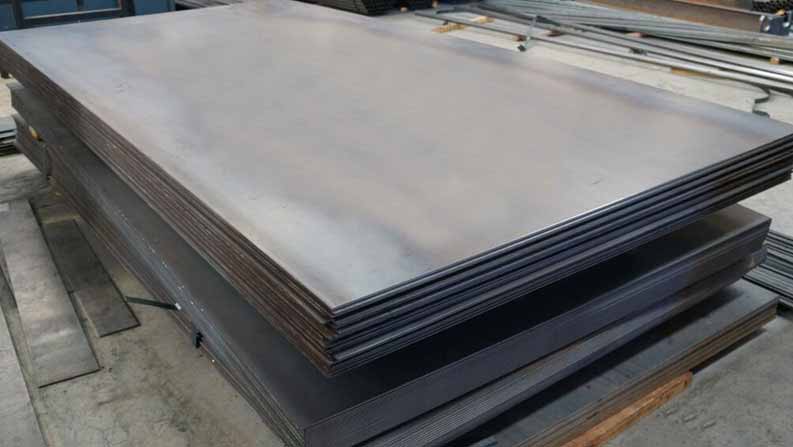

In industries where heavy abrasion, impact, and continuous material flow are part of daily operations, durability is not optional—it is essential. Rockstar 450 Plates are designed to deliver superior wear resistance while maintaining structural stability. Positioned between medium and very high hardness wear plates, this grade provides a strong balance of toughness and abrasion resistance. It is widely chosen for applications where equipment must endure harsh working conditions without frequent maintenance or replacement.

Body

Rockstar 450 Plates are abrasion-resistant steel plates with a nominal hardness of approximately 450 HB. This increased hardness level provides greater protection against sliding wear, surface scratching, and impact abrasion compared to lower-grade wear plates. The manufacturing process ensures uniform hardness across the entire plate thickness, resulting in consistent mechanical performance.

These plates are specifically developed for environments where materials such as crushed stone, coal, sand, and ore create continuous surface friction. Ordinary structural steel tends to wear quickly under such conditions, leading to downtime and higher operating costs. Rockstar 450 Plates significantly reduce wear-related damage, extending equipment service life and improving operational reliability.

Despite their higher hardness, Rockstar 450 Plates maintain adequate toughness, allowing them to withstand dynamic loads and moderate impact without cracking under proper working conditions. With suitable fabrication techniques, they can be cut, bent, and welded to create customized components such as liners, buckets, chutes, and reinforcements. Their dimensional accuracy and strength support reliable installation and long-term use.

By minimizing maintenance frequency and replacement cycles, Rockstar 450 Plates contribute to improved productivity and cost efficiency in heavy-duty industries.

Key Features of Rockstar 450 Plates

Approximate hardness of 450 HB for enhanced abrasion resistance

Uniform mechanical properties throughout plate thickness

Strong resistance to sliding and impact wear

Good balance between hardness and toughness

Suitable for fabrication with appropriate procedures

Extended service life compared to conventional steel plates

These features make Rockstar 450 Plates a reliable solution for high-wear industrial environments.

Types of Rockstar 450 Plates

Rockstar 450 Plates are available in various forms to meet different operational requirements, including:

Standard Wear Plates for general heavy-duty applications

Heavy Thickness Plates for severe abrasion and impact zones

Cut-to-Size Plates tailored to specific equipment components

Fabricated Wear Parts produced from Rockstar 450 steel

This range allows flexibility in equipment design and manufacturing.

Applications of Rockstar 450 Plates

Due to their durability and wear resistance, Rockstar 450 Plates are widely used in:

Mining and quarry machinery

Dump truck bodies and liners

Excavator and loader attachments

Crushers, screens, and hoppers

Conveyor systems and transfer points

Cement and aggregate processing plants

Construction and earthmoving equipment

Their performance ensures consistent reliability in environments exposed to heavy mechanical stress.

Conclusion

Rockstar 450 Plates offer a dependable combination of enhanced hardness, structural strength, and fabrication versatility. Designed to withstand severe abrasion and demanding working conditions, they help extend equipment lifespan and reduce maintenance costs. For industries seeking reliable wear protection and long-term operational efficiency, Rockstar 450 Plates provide a practical and durable solution.